- Automatic Wood Pallet Block Nailing Machine -

Automatic Wood Pallet Block Nailing Machine

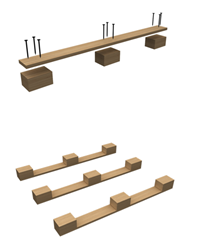

Introduction of wood pallet block nailing machine

When the automatic pallet block connecting machine is running, put the cut wood and pallet legs together on the automatic pallet leg nailing machine, and the wooden pallet leg nailing machine can automatically connect the wood planks and the foot block together, and the connection is very tight. The wooden leg nailing machine is divided into three-legged pallet nailing machine, four-legged pallet nailer machine and five-legged pallet connecting machine according to the number of legs connected by wooden boards. The pallet block connecting machine produced by our company can nail all kinds of European standard pallet blocks, solid wood pallet blocks and shaving pallet blocks.

The structure of the wooden pallet nailer machine

The wooden pallet connecting machine is mainly composed of two parts, one is the feeding part, the feeding part can send the board and the foot pier to the nailing position. The second is the nailing part, the nail gun connects the board and the foot pier together. This machine has high production efficiency, only one worker can complete all operations, saving labor costs. The machine has a wide range of applications. The machine is controlled by PLC during operation, and parameters can be set on the touch screen on the machine. The entire process can be automatically operated without manual intervention, which greatly improves work efficiency.

Technical parameters of the Pallet Block Nailing Machine

| Model | PM-1300LD | |

| Size |  |

|

| Speed |

|

600 pcs/hour |

| Nail qty & position |  |

|

| Power |

|

0.75 kW servo motor |

The working principle of the wooden pallet feet nailing machine

The operation of the wooden pallet block nailer is driven by a chain. The wood plank is moved under the nail gun, which then nails the wood plank and the block together. This machine can customize the size of nails according to customer requirements, and the normal size is below 1300mm. The nail gun and other accessories of the pallet nailing machine can use the brand specified by the customer. The number of nails can be adjusted according to the needs. The position of the nails is neat. During the nailing process of the machine, there will be no problems of missing nails and weak nails.

Advantages of Automatic Pallet Leg Nailing Machine

Wooden pallet block nailing machine has high degree of automation, simple structure and convenient maintenance. The size of nailing the pallet can be adjusted manually or through a program on the machine. The operating system of the pallet block nail machine adopts PLC control, and workers can operate it through the touch screen. The nail gun adopts the Stanley brand, and the nail position is determined by the servo motor and the induction switch. The pallet leg nailing machine is easy to operate, and one person can automatically complete feeding, pressing, nailing, cutting to fixed length, etc., with high efficiency.

- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Irish

- Greek

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

- Kinyarwanda

- Tatar

- Oriya

- Turkmen

- Uyghur