- Factory wholesale Wood Drum Chipper Machine - Wood Drum Chipping Machine,Wooden Chipping Machine – ThoYu -

Factory wholesale Wood Drum Chipper Machine - Wood Drum Chipping Machine,Wooden Chipping Machine – ThoYu

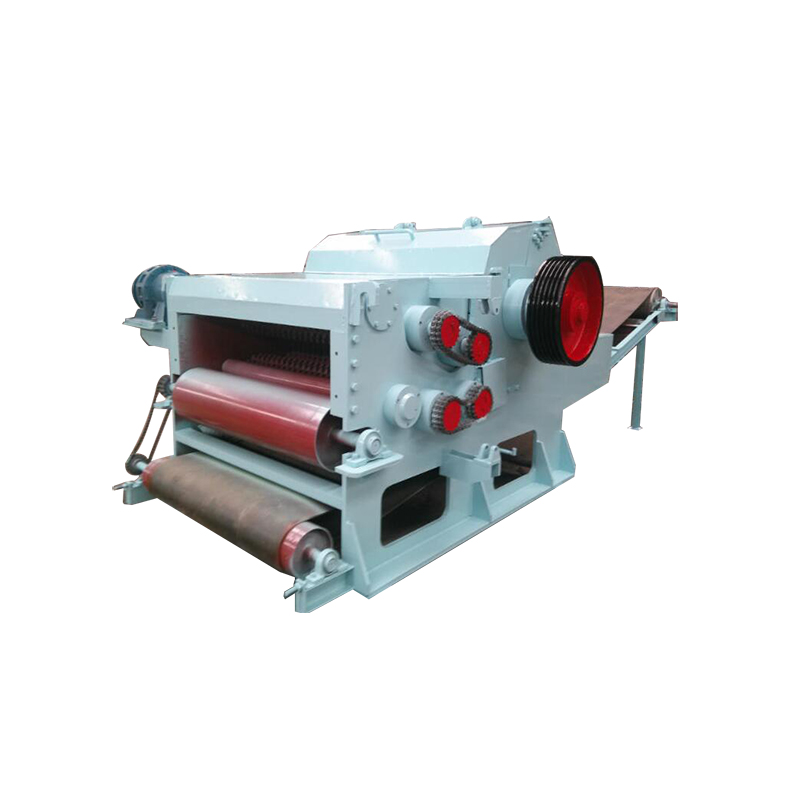

Introduction of Drum Chipper Machine

How A Drum Chipper Machine Works

The wood chipping machines for sale is composed of body, cutter, upper and lower feeding rollers, conveyor belt, hydraulic system and other parts. The wood is fed from the feeding port. When the wood comes into contact with the cutting blade, it will be cut with the high-speed rotation of the cutting blade. The cut wood chips are generated by the fan blades on the cutting blade in the cutting chamber. high-speed steam flow out. A screen is installed under the knife roller. The mesh size of the screen can be adjusted according to the needs of customers. The size of the wood chips after cutting can be adjusted by adjusting the size of the drying mesh.

Parameters of Drum Wood Chipper Machine

| Model | PMBX-216 | PMBX-218 |

| Feeding port size | 300×500mm | 350×700mm |

| Knife quantity | 2 | 2 |

| Max process size | 230mm | 300mm |

| Wood chips size | 30mm | 25-35mm |

| Production capacity | 6-8tons/hour | 8-12tons/hour |

| Motor power | 55 Kw | 110Kw |

| Weight | 5 Ton | 7 Ton |

| Overall size | 1.8×1.9×1.21 meter | 3.2×2.4×1.6 meter |

Advantages of Chipping Machines For Sale

Our Service

1. We have a professional wood processing equipment installation team. According to the needs of customers, we install it for you at a professional level, and strive to make customers happy.

2. Our company will provide long-term after-sales tracking service for various series of wood chipping equipment sold, so that our enthusiastic service can ensure the satisfaction of every customer!

We have worked with many companies, but this time is the ,detailed explanation, timely delivery and quality qualified, nice!