Recently, at the request of a leading wooden pallet manufacturer in Greece, we successfully completed the delivery of a set of advanced automated pallet block production line. With the continuous expansion of the customer’s business territory and the gradual increase of the production scale, the problem of waste disposal has become a key issue that needs to be solved on the way of its development. Our company with keen market insight and professional technical team, in-depth understanding of the actual plight of the customer, carefully create a set of customized solutions.

This set of automated pallet block production line integrates the cutting-edge wood processing technology, with a high degree of automation and intelligent operation mode. It can not only efficiently resource utilization of waste wood, to achieve green production, but also through a unique production process, the manufacture of high-quality pallet blocks, to replace the traditional solid wood blocks. After the actual data verification, after adopting the composite pallet blocks, the customer’s pallet production cost can be reduced by 10%, effectively enhancing its price advantage and comprehensive competitiveness in the international market.

Throughout the cooperation process, our company always puts customer needs in the first place, and has set up a project team composed of professionals from various fields. From the fine control of production link to the strict inspection of product quality, each step strictly follows the international standards and customer-specific requirements, and makes every effort to ensure that the equipment can be delivered on time and with high quality. Considering the precision, volume and weight of the equipment, we carefully planned the transportation plan with the help of professional logistics evaluation system, and finally decided to use four high-bay containers for transportation to ensure the safety and integrity of the equipment during the long-distance transportation.

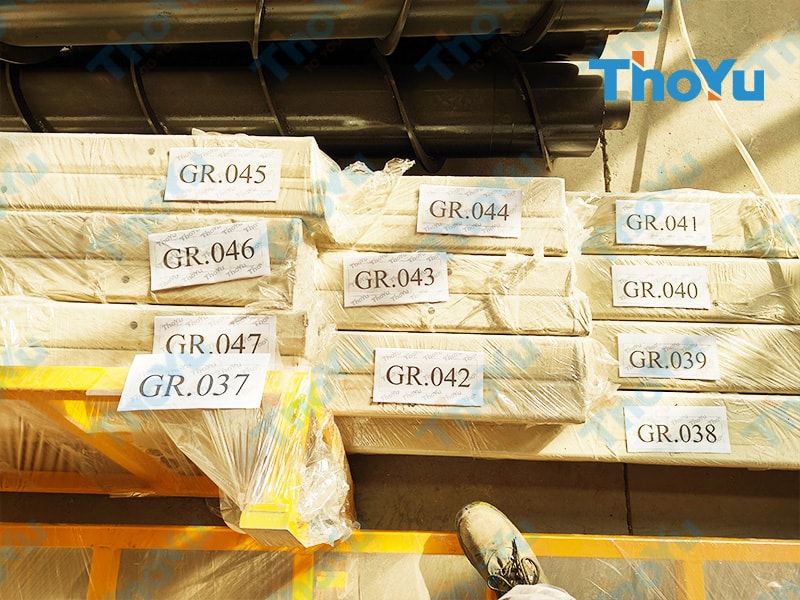

In order to ensure the smooth completion of this delivery task, our company has made a detailed loading plan in advance, based on the professional skills and experience of the staff, and carried out a reasonable division of labor. After the loading work was officially started on January 13th, all the staff held a high sense of responsibility and worked strictly according to the operation procedures. After a whole day’s hard work, all the equipment and spare parts were loaded into the containers in good condition and with accurate quantities. After the loading was completed, the transportation vehicle immediately departed and sped towards the port, carrying our sincere commitment and the customer’s earnest expectation to Greece.

This successful delivery fully demonstrates our strong strength in technology research and development and service guarantee, and further deepens the cooperation and friendship with Greek customers. Looking ahead, our company will continue to increase investment in technological innovation in pallet nailing machine, compressed pallet machine and plastic pallet machine, continue to optimize the quality of products and services, provide better and more efficient solutions for global customers, and work together to create a better future.

Post time: Jan-15-2025