Transforming scrap wood into marketable products like molded wood pallets or compressed wood blocks is an excellent way to recycle and profit from waste. Here’s a comprehensive guide to help you start:

1. Evaluate Your Scrap Wood Inventory

- Volume: Determine how much wood waste you have for processing.

- Condition: Identify contaminants such as nails, paint, or dirt, and separate reusable wood from unusable material.

2. Select Your Target Product

- Molded Wood Pallets:

- Widely used in shipping and logistics.

- Require wood fibers and glue molded under high pressure and heat.

- Compressed Wood Blocks:

- Commonly used as pallet feet or in construction applications.

- Made by compressing wood particles mixed with glue.

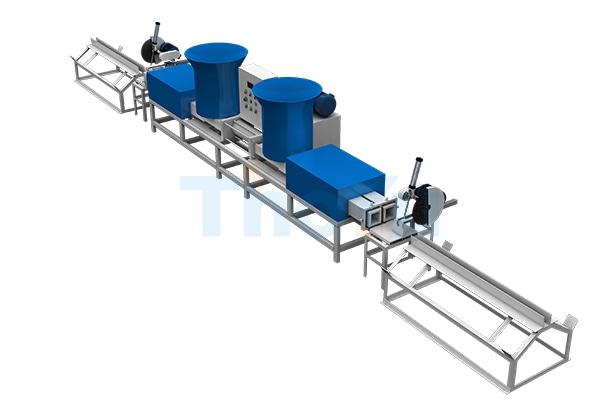

3. Acquire Essential Equipment

For Molded Wood Pallets:

- Wood Chipper/Crusher: Reduces scrap wood into fine particles.

- Dryer: Lowers moisture content to below 10%.

- Glue Mixer: Combines wood fibers with resin or glue.

- Compressed Pallet Machine: Shapes and compresses wood fibers into pallets.

For Compressed Wood Blocks:

- Wood Chipper/Crusher: Breaks down wood into smaller chips.

- Drying Machine: Ensures the material is moisture-free.

- Glue Mixing System: Prepares the glue-wood mixture.

- Pallet Block Machine: Compresses and extrudes wood blocks.

4. Design Your Production Workflow

- Preparation: Remove contaminants like nails and separate usable wood.

- Chipping/Crushing: Convert wood into chips or fibers.

- Drying: Use industrial dryers to reduce moisture.

- Mixing: Blend wood particles with glues in precise proportions.

- Pressing/Molding: Use hydraulic presses to mold the mixture into pallets or blocks under high pressure and temperature.

- Cooling and Finishing: Let the products cool and cure before packaging them for sale.

5. Find Market Opportunities

- Logistics Companies: Supply molded pallets for shipping.

- Furniture and Construction: Offer compressed blocks for structural use.

- B2B Platforms: List your products on online marketplaces.

- Eco-conscious Buyers: Highlight your recycling and sustainability efforts.

6. Prioritize Quality and Sustainability

- Maintain high product standards to compete in the market.

- Obtain certifications for eco-friendly or sustainable manufacturing practices.

7. Optimize for Profitability

- Minimize material wastage during production.

- Invest in energy-efficient equipment.

- Explore automation to increase efficiency and reduce labor costs.

With this process, you can turn scrap wood into highly marketable products while promoting sustainable manufacturing. Are you ready to get started, or do you need help with a specific part of the process?

Write your message here and send it to us

Post time: Dec-09-2024