- Pallet Block Cutting Machine,Pallet Block Saw -

Pallet Block Cutting Machine,Pallet Block Saw

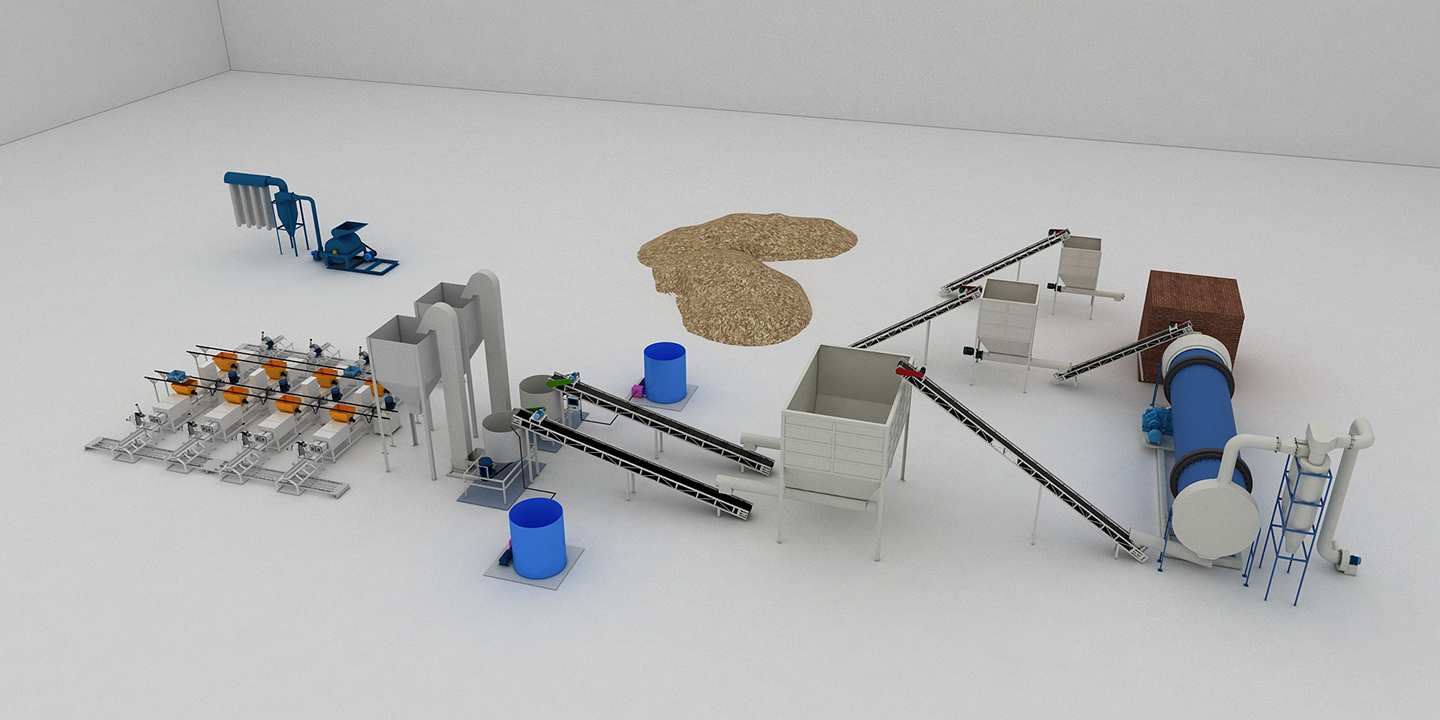

Introduction of multi-blade pallet block cutting saw

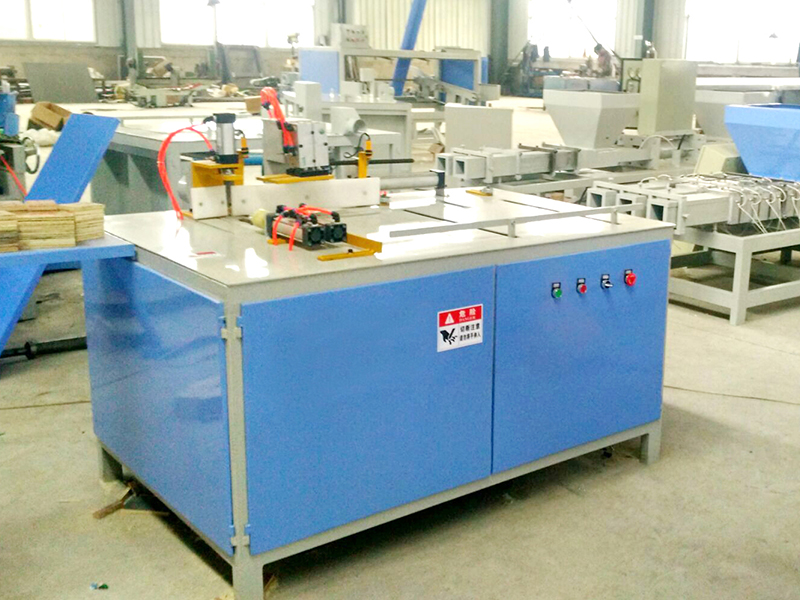

The cnc pallet block cutting machine is improved on the basis of the ordinary saw. The equipment can be used for automatic cutting of multi-layer board pallet blocks and sawdust pallet blocks. The machine can be automatically loaded. Driven by the cylinder, the wood block moves forward automatically, and then the saw blade cuts the wood block. During the operation of the machine, there is no need for manual intervention, which saves manpower and is safe and efficient.

The working principle of wood block cutting machine

First, place the long wooden block on the work panel of the machine. After starting the wood cutting saw, the wood pallet block automatically moves forward under the push of the cylinder. The inductive switch of the compression device senses the block and compresses it, then pushes the pallet foot block to the sawing system. When the wood pallet block is sent to the sawing system of the wood block cutter, the saw blade automatically starts to lift and cut the wood block. The equipment is equipped with a dust removal outlet, which can connect the waste wood chips to the workshop dust bag for discharge.

Parameters of automatic pallet legs cutting saw

| Model |

PM-1250DP |

| Cutting size |

|

| Capacity |

|

| Power |

|

| Blade diamater |

|

Features of Multi-Blade Wood Block Cutting Machine

1. High precision: The pallet block cutting sawing is relatively accurate, the cutting surface is completely vertical, the intersecting surface is smooth, and there is no excess leftover material.

2. High efficiency: fast working speed, 1800 pieces/hour cutting speed, can work continuously for 24 hours.

3. Simple operation: 1 worker can complete all the work, just put the pallet foot block on the workbench of the block cutting machine.

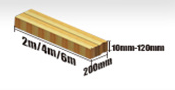

4. The size can be adjusted: the pallet blocks of different sizes can be cut according to the needs, and the block cutting machine can be adjusted.

Advantages of Automatic Wood Block Cutting Machine

The cutting position of the automatic block cutting machine is accurate, the surface is flat, there is no cutting mark, and the length of each section is the same. The cutting speed of the machine can be adjusted, and the cutting speed of the automatic pallet block cutting machine can be adjusted on the control panel of the machine. After inputting the cutting length, there is no need for manual adjustment, and it is suitable for cutting foot blocks of various sizes. The processed surface after cutting is smooth and flat, and no secondary processing is required.

- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Irish

- Greek

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

- Kinyarwanda

- Tatar

- Oriya

- Turkmen

- Uyghur

5m3/hour

5m3/hour 22kW

22kW 355mm

355mm