- Plastic Extruder Machine,Plastic Extrusion Machine -

Plastic Extruder Machine,Plastic Extrusion Machine

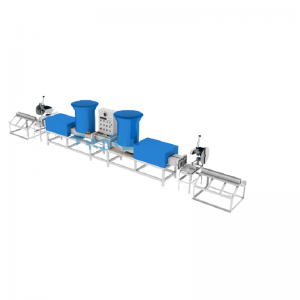

Introduction of plastic extruder machine

plastic recycling extruder machine is a plastic equipment for melting and extruding plastic. The plastic is melted through the plastic extrusion equipment's heating device and extrusion device. The plastic extruder for sale has the advantages of high efficiency and low cost, and is an essential equipment for molded plastic pallet production line. The recycled plastic extruder machine is a single screw plastic extruder with high processing efficiency. The machine is equipped with feeding system, transmission system, extrusion system, heating system, automatic control system,which have the characteristics of stable operation, high efficiency and easy maintenance.

How a plastic extrusion machine works

The plastic in the plastic extruder machine is melted under the heating of the electric heating tube, and the solid plastic is transformed into a uniform melt under the extrusion and shearing action of the screw. The raw material enters the plastic recycling extruder through the hopper above the machine, and there is a feeding screw in the hopper, which can transport the material evenly into the plastic recycling extruder machine. The feeding speed can be controlled by controlling the speed of the geared motor above the machine.

Technical parameters of plastic extruder machine

| model: | PM-LJ180 |

| Aspect ratio | 33:1 |

| Screw diameter | 180mm |

| barrel length | 5940mm |

| main motor power | 110 kw |

| Host speed control device | 75KW |

Features of plastic extruder machine

1. The plastic extrusion equipment has high output, low energy consumption and low manufacturing cost, and can be used for processing various plastic materials. It has applications in various industries, usually in the plastic product processing industry.

2. The plastic extruder machine has the advantages of high processing efficiency, good product quality and safe operation. the conveying volume of the screw is larger, the extrusion volume is relatively stable, the material stays in the barrel for a long time, and the mixing is uniform.

- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Irish

- Greek

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

- Kinyarwanda

- Tatar

- Oriya

- Turkmen

- Uyghur