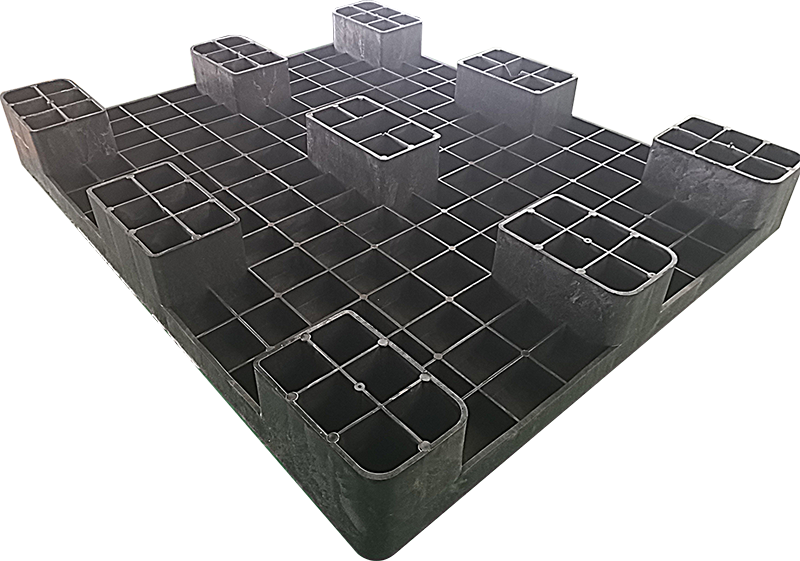

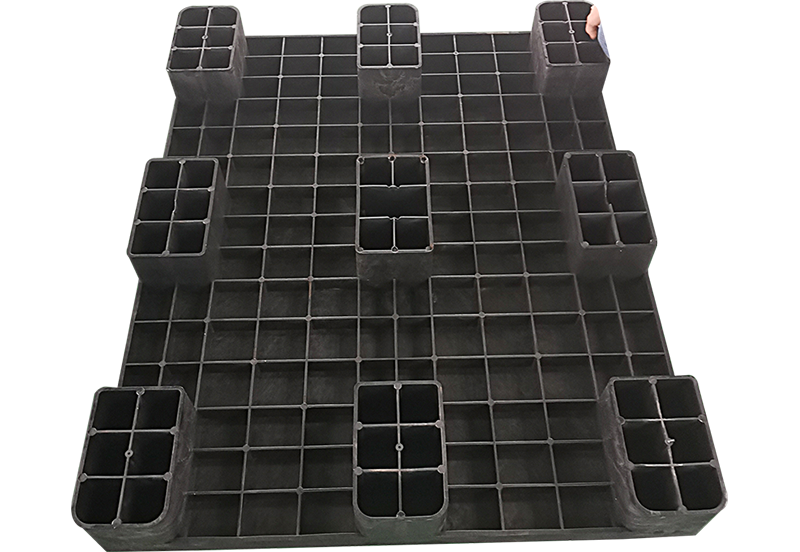

Plastic pallets are very common in life. In logistics transportation and warehouse storage, pallets are usually used to carry these goods in order to facilitate the loading and unloading, transportation, storage and distribution of goods. Due to the good waterproof effect and long service life of plastic pallets, with the rise of the logistics industry, the market demand for plastic pallets is getting higher and higher, and the production of plastic pallets has become a good investment.

Traditional plastic pallets are made of polypropylene (PP plastic) and polyethylene (PE plastic). Plastic pallets made of polyethylene (PE plastic) have good wear resistance, strong impact resistance, light weight, long service life, and corrosion resistance due to the presence of organic solvents. The plastic tray made of polypropylene (PP plastic) is light in weight, good in toughness, good in chemical resistance, and has good mechanical properties, including strength, rigidity, transparency, impact resistance and corrosion resistance. At the same time, PE and PP are widely used in the plastic processing industry. PE is mainly used for packaging (plastic bags, plastic films, geomembranes) and various containers, bottles and plastic packaging. Polypropylene (PP plastic) has excellent comprehensive properties and can be heat-resistant and corrosion-resistant. Common products include basins, barrels, furniture, films, woven bags, bottle caps, car bumpers, etc. These plastic products are very common in life, and also generate a lot of plastic waste. These waste plastics can be used to recycle and produce various plastic pallets.

Traditional plastic pallet production lines usually use injection molding to produce plastic pallets. In this way, if you want to use recycled plastics of various PE and PP materials, you need to granulate first. Due to the high requirements on the performance and cleanliness of plastic raw materials, operation Improper use can easily lead to blockage of the injection hole of the machine. The production process of injection molding is complex, and the technical requirements for workers are relatively high. Plastic raw material costs and processing costs are high. In response to the above problems, our company has developed a new fully automatic production line using waste plastic to produce plastic pallets based on years of industry experience. The compression molding process has a relatively low purity of plastic materials and plastics. Waste plastics of various materials are pulverized, melted in an extruder, and then molded into plastic trays in a plastic tray molding machine.

The plastic pallet compression molding production line can produce pallets with waste plastics of various materials, and can customize machines of various models and capacities for you. It is an environmentally friendly waste plastic processing equipment that meets the needs of the market.

Post time: Oct-13-2022