The amount of plastic waste produced each year is increasing and it’s only getting worse. Fortunately, there are ways to recycle this waste and give it new life. One such way is by using it to create pallets. Pallets are an essential part of many businesses, but they can be expensive and difficult to find. By using recycled plastic, you can create your own pallets at a fraction of the cost. Plus, you’ll be doing your part to help reduce plastic waste. We’ll show you how to use a plastic machine to recycle plastic waste into pallets. We’ll also provide some tips on how to choose the right machine for your needs.

Plastic pallet machines are an ideal way to recycle waste plastic and turn it into a valuable product. By using a plastic pallet machine, you can create sturdy, durable pallets that can be used in a variety of applications. Plastic pallets are an excellent alternative to traditional wooden pallets, and they offer many benefits including being more cost-effective, lighter in weight, and more resistant to pests and rot.

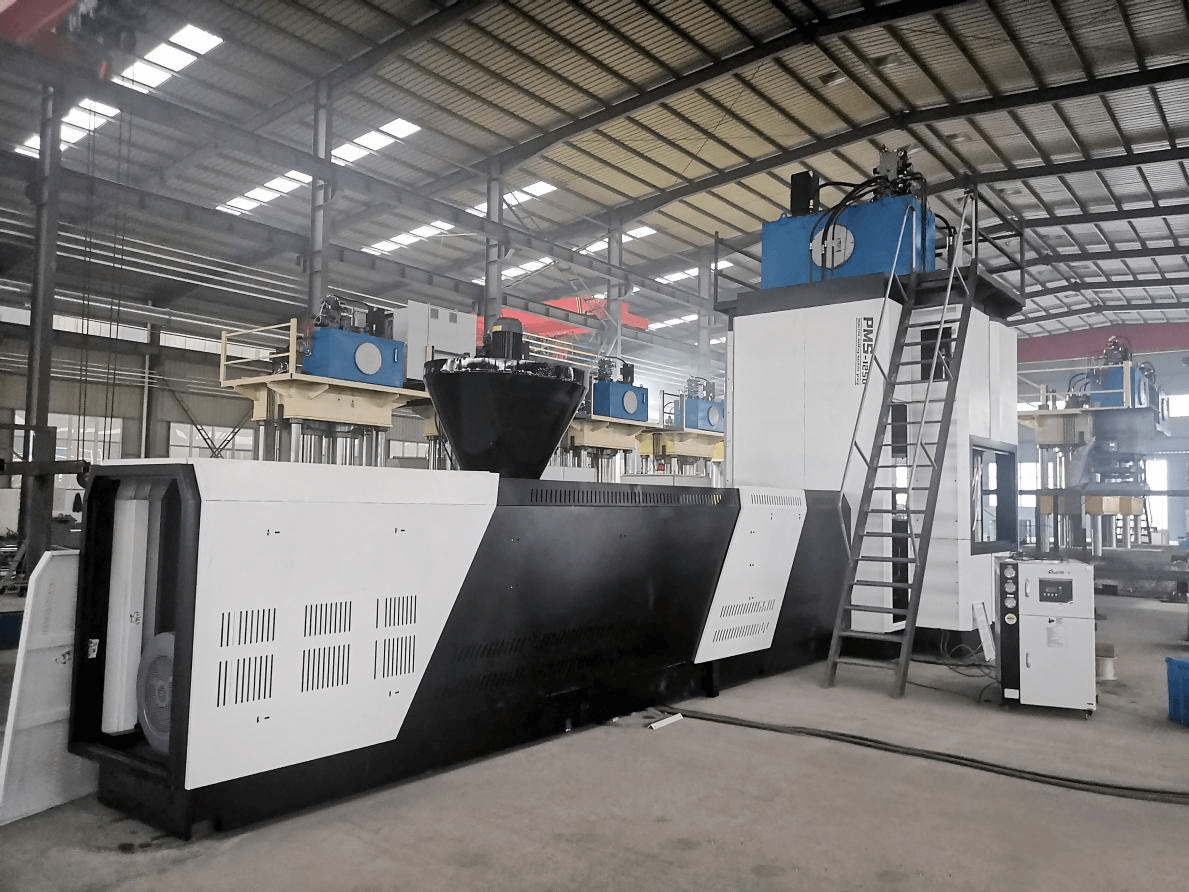

Our company usually uses plastic pallet molding technology to produce plastic pallet, which saves more money than injection molding. First, the waste plastic is conveyed into the extruder, where it undergoes high temperature and high pressure to form molten plastic, and then it is formed into a molded plastic pallet in our molded pallet machine.

If you're interested in recycling waste plastic and turning it into something useful, a plastic pallet machine is a great option. With a plastic pallet machine, you can create strong, durable pallets that can be used for a variety of purposes. Plastic is one of the most versatile materials in the world. It can be used to make everything from bottles and containers to packaging and products. However, when it comes to waste plastic, there are many ways that it can be recycled and reused. One of the most popular ways to recycle waste plastic is by using a plastic machine to create pallets.using a plastic machine to create pallets is an excellent way to do so. Not only does this help to reduce the amount of waste plastic in landfills, but it also helps to create a product that can be used over again.

It is very popular to produce molded pallets from recycled plastic, there are a few things you will need in order to get started. First, you will need a source of waste plastic. This can be anything from packaging material to unused products. Once you have a source of waste plastic, you will need a way to shred or chop it into small pieces. A plastic machine can typically do this job quite easily. Once you have your shredded or chopped up waste plastic, it's time to start creating your pallets. There are two main types of machines that can be used for this purpose: an injection molding machine or an extrusion machine.

What are the benefits of using a waste plastic to make a pallet?

When it comes to reusing and recycling materials, there are many benefits to using a waste plastic to make a pallet. For starters, doing so can help reduce the amount of waste that is sent to landfills each year. In addition, using recycled materials can also help save money and resources.

Another benefit of using recycled materials is that it can help reduce the carbon footprint of a business or individual. Using recycled plastics requires less energy to produce than new plastics, which helps conserve fossil fuels and reduces emissions.Finally, using recycled materials can also help create jobs in the recycling industry. By supporting businesses that recycle waste plastics, you can help create an industry that provides green jobs and supports sustainability.

We hope that this article has shown you how plastic waste can be recycled is useful for you. By using a plastic molding machine, we can help reduce the amount of plastic waste that ends up in landfills. Not only is this good for the environment, but it also helps us save money on buying new pallets. If you're interested in learning more about how to recycle plastic, please check out our website.

Post time: Nov-25-2022